Refrigerated Air Dryer: How It Works and Why It Matters

Compressed air is essential in many industries—from manufacturing and automotive to food processing and pharmaceuticals. However, one challenge remains constant: moisture. When warm, humid air

Lingyu’s advanced refrigerated air dryers are engineered to provide professional, energy-efficient, and reliable compressed air drying solutions for industrial applications.

By cooling compressed air and condensing water vapor, our refrigerated compressed air dryers effectively remove moisture and protect downstream equipment from corrosion, performance loss, and unexpected failures. With processing capacities of up to 15,900 CFM, our systems are designed to meet a wide range of industrial requirements, ensuring stable operation and enhanced productivity.

Explore our full range of refrigerated air dryers below and request a quote to find the right solution for your compressed air system.

This 75 CFM (air-cooled) refrigerated air dryer is a reliable and energy-efficient solution, specifically designed to remove moisture from compressed air systems. It is ideal for small to medium industrial applications, providing clean, dry compressed air with a stable pressure dew point. With its compact design and air-cooled operation, this 75 CFM (air-cooled) refrigerated air dryer ensures long-term, stable performance while minimizing maintenance requirements.

Whether you operate a workshop, packaging line, or small production facility, the 75 CFM refrigerated air dryer (air-cooled) is the perfect choice to protect your pneumatic tools and equipment from moisture-related issues.

The 25/35/50 CFM Air-Cooled Refrigerated Air Dryer from Lingyu is a compact and energy-efficient solution for small to medium compressed air systems. It efficiently removes moisture and maintains a stable dew point, providing clean, dry air for tools, machinery, and production processes.

With its reliable air-cooled design, low power consumption, and easy operation, this dryer series helps improve air system performance, reduce maintenance costs, and protect equipment from moisture-related damage.

The 200 CFM refrigerated air dryer (air cooled) is a compact and efficient solution for removing moisture from compressed air systems. Designed for mid-sized industrial applications, this dryer ensures clean, dry air to protect downstream equipment from corrosion, contamination, and failure.

With air-cooled technology and stable dew point performance, the 200 CFM refrigerated air dryer (air cooled) offers a reliable and energy-saving approach to compressed air drying.

The 1340 SCFM refrigerated air dryer (water cooled) is a high-performance moisture removal system designed for industrial applications that demand clean and dry compressed air. Engineered for reliability and efficiency, this water-cooled model uses chilled water circulation to condense and remove moisture from compressed air streams with a rated capacity of 1340 SCFM.

Whether your facility operates in high-temperature environments or uses centralized water cooling systems, the 1340 SCFM refrigerated air dryer (water cooled) is your best solution for delivering constant dew point control and protection for downstream equipment.

The 1130 SCFM refrigerated air dryer (air cooled) is a high-capacity, energy-efficient solution designed to eliminate moisture from compressed air systems in demanding industrial environments. With a robust air-cooled refrigeration system and a processing capacity of 1130 SCFM, this dryer delivers consistent performance and reliable dew point control to protect downstream equipment and ensure production continuity.

Whether you’re operating in a manufacturing plant, automotive facility, or heavy-duty processing site, the 1130 SCFM refrigerated air dryer (air cooled) guarantees optimal air quality while reducing maintenance costs and energy waste.

The 100 CFM refrigerated air dryer (air cooled) is a high-performance compressed air treatment solution designed to remove moisture from compressed air systems efficiently. Ideal for small to medium-sized industrial applications, this air dryer ensures clean, dry air to protect downstream equipment and improve productivity.

With advanced air-cooling technology, compact design, and energy-efficient components, the 100 CFM refrigerated air dryer (air cooled) is the perfect choice for users seeking reliability, efficiency, and long service life.

The 3885 CFM water-cooled refrigerated air dryer is an industrial moisture-removal system designed for facilities that require stable and efficient drying performance. Suitable for large compressed air networks, it provides reliable dew point control and long-term protection for downstream equipment in demanding environments.

Engineered for continuous operation, this high-capacity unit combines advanced refrigeration components with an energy-efficient water-cooling design. Its consistent performance makes it ideal for industries such as petrochemical processing, metal fabrication, manufacturing, and pharmaceutical production—any application where clean, dry compressed air is essential.

The 4238 CFM refrigerated air dryer (water cooled) is a high-capacity, industrial-grade dryer designed to eliminate moisture from large compressed air systems. Built with a powerful water-cooled refrigeration circuit, this dryer ensures reliable and continuous moisture removal with a stable pressure dew point. For industries that demand high airflow rates and dependable air quality, the 4238 CFM refrigerated air dryer (water cooled) is the ideal solution.

Whether operating in petrochemical, textile, food processing, or manufacturing sectors, the 4238 CFM refrigerated air dryer provides exceptional performance, energy efficiency, and long-term durability.

The 8830 CFM refrigerated air dryer (water cooled) is a top-tier industrial solution engineered to remove moisture from large-scale compressed air systems. Built for ultra-high capacity applications, this dryer ensures consistently dry air with a stable dew point and superior thermal control using an advanced water-cooled condenser system.

Designed for 24/7 operation in the most demanding environments, the 8830 CFM refrigerated air dryer (water cooled) guarantees optimal air quality, minimal pressure loss, and extended equipment lifespan across heavy-duty industries.

The air is pure, no secondary pollution, integrated skid-mounted design, compact structure, stable dew point, remarkable water removal effect.

Refrigerated air dryers are essential components in industrial compressed air systems, designed to remove moisture from compressed air before it reaches downstream equipment. Excess moisture in compressed air can cause corrosion, damage machinery, and reduce overall system efficiency.

Lingyu refrigerated compressed air dryers work by cooling the compressed air, condensing water vapor into liquid form, and removing it from the air stream. The result is clean, dry compressed air that protects equipment, improves reliability, and ensures consistent industrial performance.

Refrigerated air dryers play a critical role in maintaining air quality, operational efficiency, and system reliability across a wide range of industrial environments.

1. Corrosion Prevention: Moisture in compressed air is a leading cause of rust and corrosion in pipelines, valves, and pneumatic tools. Our refrigerated compressed air dryers effectively eliminate moisture, protecting critical components and extending equipment service life.

2. Enhanced Operational Efficiency: By delivering consistently dry compressed air, refrigerated air dryers help pneumatic tools and machinery operate at peak performance, reduce maintenance requirements, and minimize unplanned downtime.

3. Ensuring Product Integrity: In industries with strict quality standards—such as food processing, pharmaceuticals, and electronics—even small amounts of moisture can compromise product quality. Refrigerated air dryers ensure a stable supply of clean, dry air to safeguard products and processes.

4. Optimizing Energy Savings: Dry compressed air improves overall system efficiency. By preventing moisture-related losses, our refrigerated air dryers help reduce energy consumption while improving system stability and reliability.

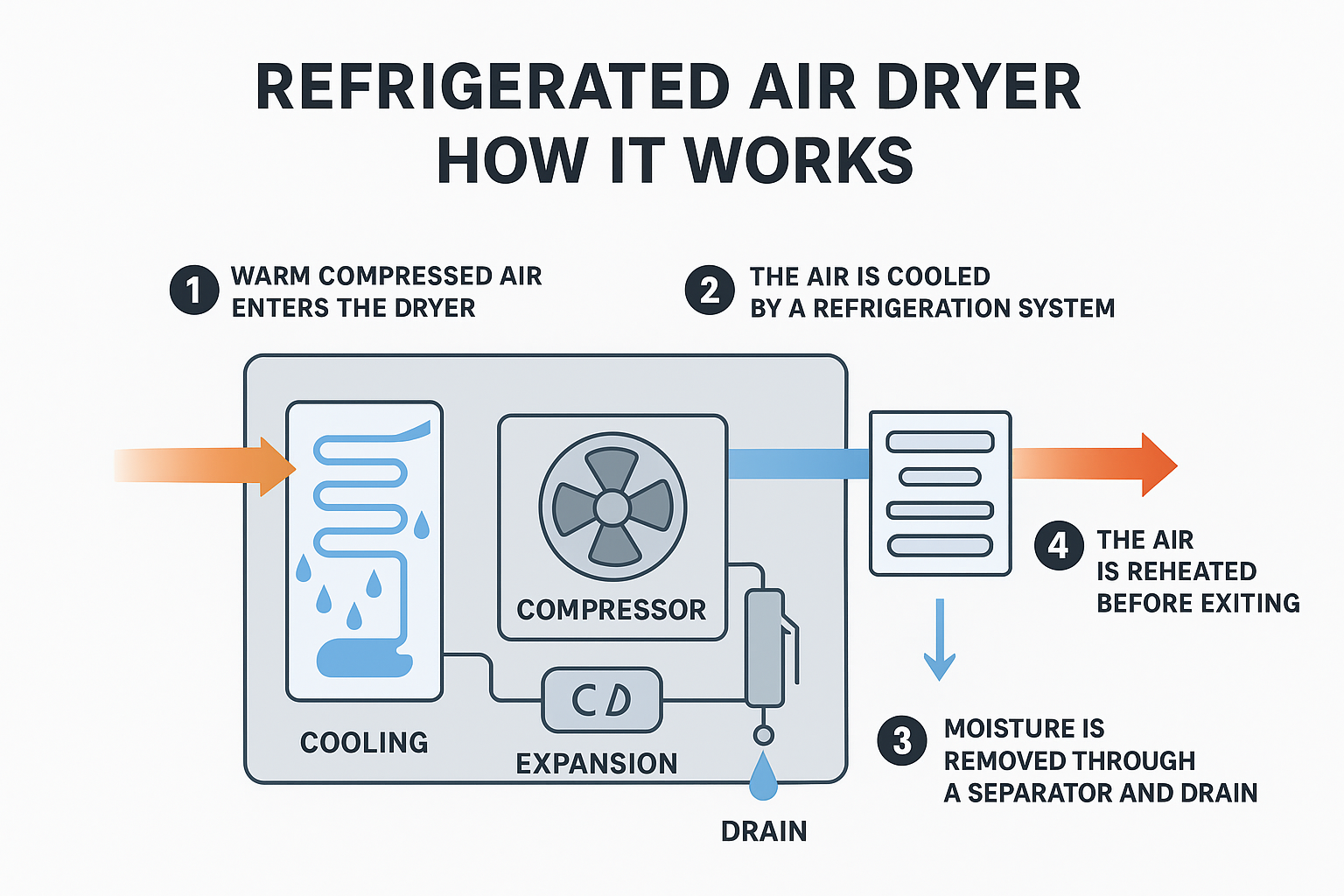

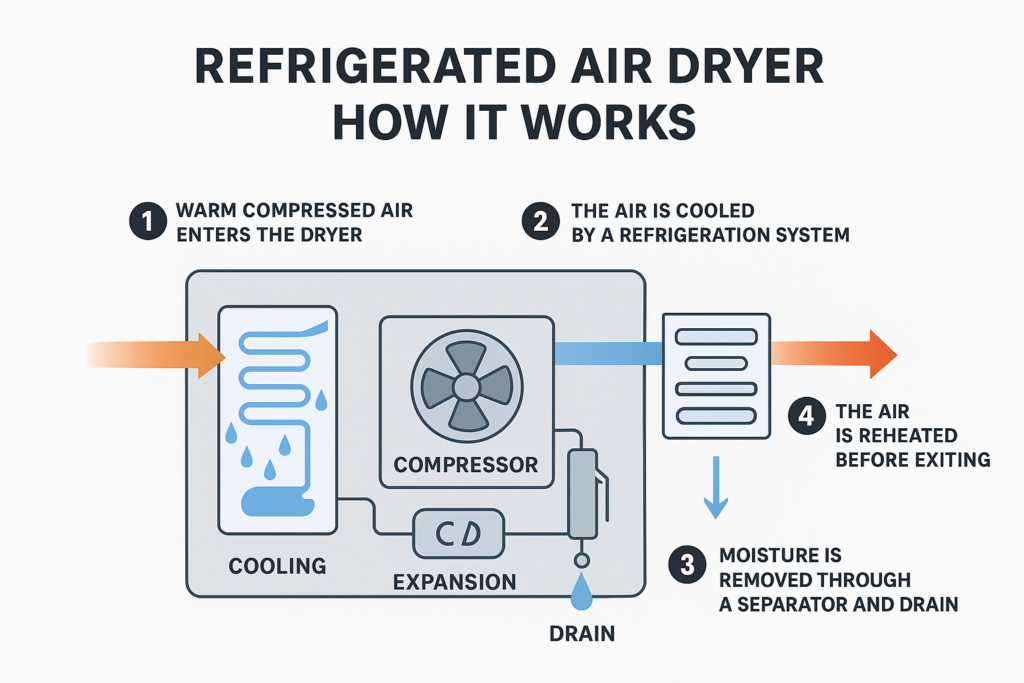

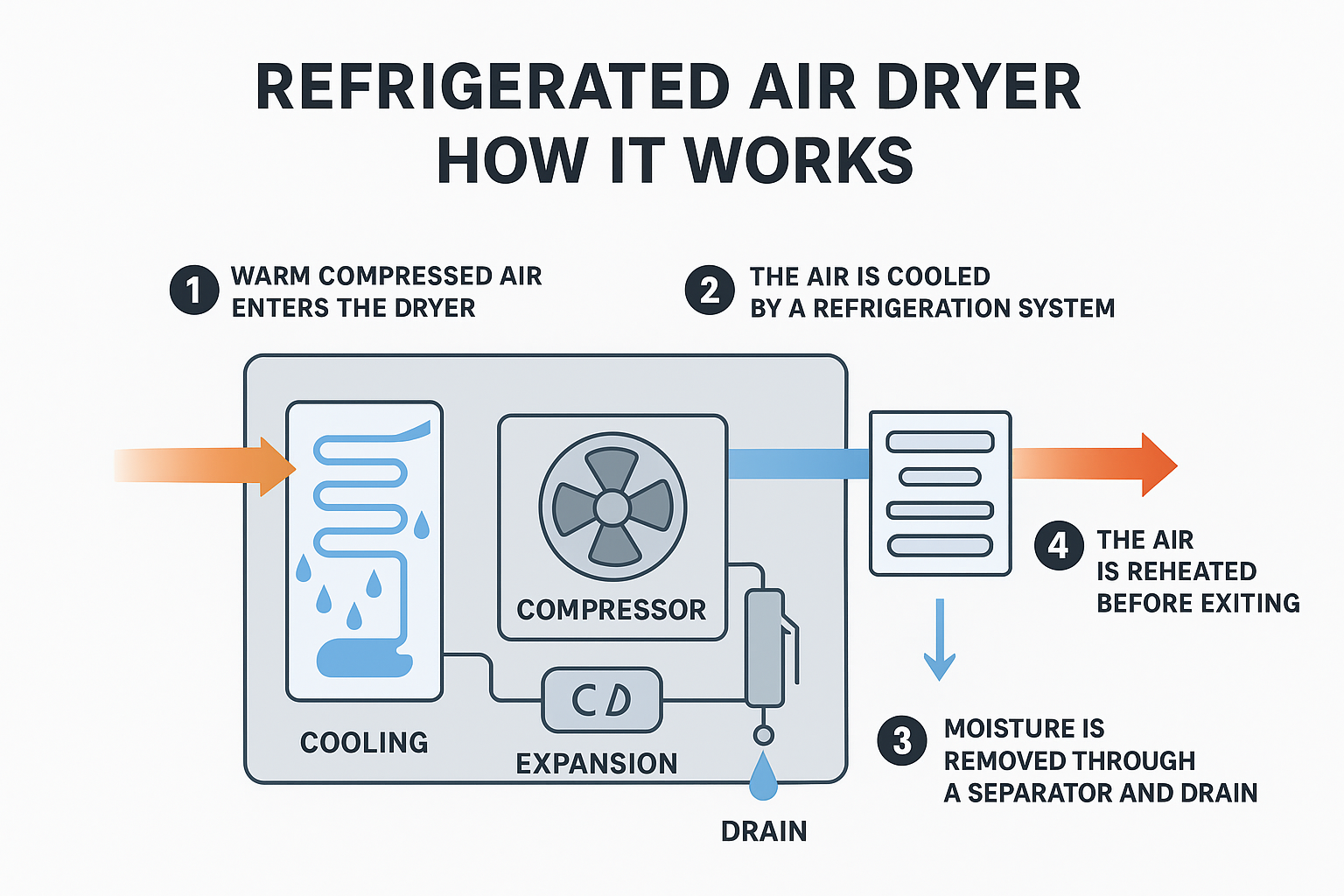

The working principle of a refrigerated air dryer is straightforward, yet highly effective. The drying process involves several key stages to ensure reliable moisture removal.

Process Overview:

Compressed Air Inlet

Hot, moisture-laden compressed air enters the refrigerated air dryer under pressure.

Cooling Stage

The refrigeration system cools the compressed air, lowering its temperature.

Condensation

As the air cools, water vapor condenses into liquid form.

Moisture Separation

Condensed water is separated from the air using an efficient separator and automatic drain.

Reheating & Discharge

The dried air is reheated slightly to prevent downstream condensation and then discharged into the compressed air system.

Lingyu offers two main types of refrigerated air dryers, each designed to meet specific operating conditions, installation environments, and cooling requirements.

Air-cooled refrigerated air dryers use ambient air as the cooling medium to remove heat from compressed air. Heat absorbed during the cooling process is released through an air-cooled condenser, allowing moisture to condense and be efficiently removed.

Air-cooled models are ideal for applications where water-cooling systems are unavailable or impractical. They are easy to install, cost-effective, and well-suited for most general industrial environments.

Water-cooled refrigerated air dryers use water as the cooling medium to dissipate heat from compressed air. Heat is transferred through a heat exchanger into a water circuit, which is typically cooled by a cooling tower or chiller system.

Water-cooled models are particularly suitable for high-capacity applications or environments with limited airflow. They offer stable performance, high efficiency, and consistent drying even under demanding operating conditions.

No.3, 2nd Street, yuanle Road, Dongsheng Town, Zhongshan City, Guangdong Province

(WeChat/WhatsApp):+8615756650906

№1:(WeChat/WhatsApp):+8618628146428

№2:(WeChat/WhatsApp):+8613823294942

Compressed air is essential in many industries—from manufacturing and automotive to food processing and pharmaceuticals. However, one challenge remains constant: moisture. When warm, humid air

In any compressed air system, moisture control is critical for maintaining performance, preventing corrosion, and extending equipment life. Without proper drying, condensation can lead to

A large refrigerated air dryer is an essential piece of equipment in many industrial compressed air systems. Designed to handle high air volumes, it removes

Selecting the right dryer is critical for maintaining clean, dry, and efficient compressed air. But how to size a refrigerated air dryer correctly is a