Compressed Air Dryer System – Types, Working Principle & Maintenance Guide

A compressed air dryer system is an essential part of any industrial compressed air setup. Its main purpose is to remove moisture from compressed air,

Lingyu offers a complete range of high-performance compressed air dryers, including refrigerated air dryers and desiccant air dryers, designed to meet diverse industrial requirements.

Backed by advanced technology and strict quality control, our air dryer solutions deliver clean, dry, and oil-free compressed air, effectively protecting your equipment and production processes from moisture and oil contamination.

Explore our full product range below and request a quote to find the ideal air dryer for your compressed air system.

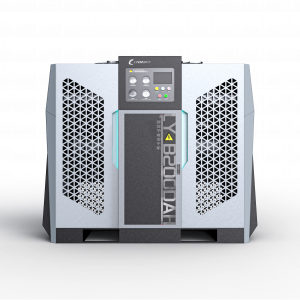

This 75 CFM (air-cooled) refrigerated air dryer is a reliable and energy-efficient solution, specifically designed to remove moisture from compressed air systems. It is ideal for small to medium industrial applications, providing clean, dry compressed air with a stable pressure dew point. With its compact design and air-cooled operation, this 75 CFM (air-cooled) refrigerated air dryer ensures long-term, stable performance while minimizing maintenance requirements.

Whether you operate a workshop, packaging line, or small production facility, the 75 CFM refrigerated air dryer (air-cooled) is the perfect choice to protect your pneumatic tools and equipment from moisture-related issues.

The 25/35/50 CFM Air-Cooled Refrigerated Air Dryer from Lingyu is a compact and energy-efficient solution for small to medium compressed air systems. It efficiently removes moisture and maintains a stable dew point, providing clean, dry air for tools, machinery, and production processes.

With its reliable air-cooled design, low power consumption, and easy operation, this dryer series helps improve air system performance, reduce maintenance costs, and protect equipment from moisture-related damage.

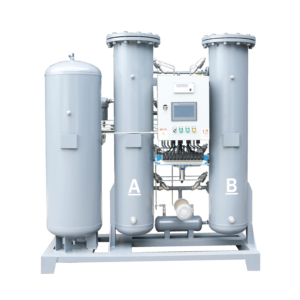

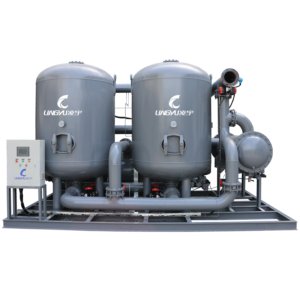

The Blower & Zero Purge Adsorption Dryer is an advanced solution for industrial compressed air systems, designed to provide continuous, energy-efficient moisture removal.

This dryer combines blower-assisted regeneration with a zero purge cycle, ensuring the regeneration process consumes no compressed air. Ambient air is drawn in by the blower, heated to desorb moisture from the adsorbent, and then cooled through an intermediate cooler in a continuous closed-loop cycle. The result is a stable low dew point with minimal energy usage, protecting downstream equipment and ensuring consistent air quality in industrial operations.

Efficient nitrogen generator providing 99.5% nitrogen purity. Designed for reliable performance in industrial, laboratory, and food packaging applications.

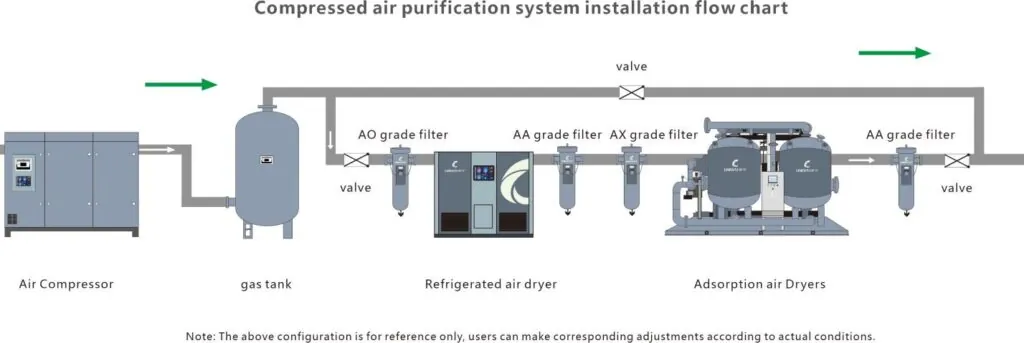

A compressed air dryer is a critical component in any compressed air system, designed to remove moisture and contaminants from compressed air. Although different drying technologies operate on distinct principles, the ultimate goal remains the same: to supply clean, dry, and stable compressed air that protects downstream equipment and ensures consistent production quality.

Refrigerated air dryers operate on the principle of condensation, similar to a household refrigerator. Incoming compressed air is cooled, causing water vapor to condense into liquid, which is then automatically separated and discharged. The dried air is reheated to prevent condensation within downstream pipelines.

Lingyu refrigerated air dryers are engineered for low pressure drop and stable performance. Models equipped with variable frequency drives automatically adjust to fluctuating air demand, significantly improving energy efficiency and operational stability.

Desiccant air dryers remove moisture from compressed air through the adsorption process. Hygroscopic materials such as activated alumina or molecular sieves capture water molecules as compressed air passes through the adsorption towers.

While one tower dries the air, the other undergoes regeneration to release absorbed moisture, ensuring a continuous supply of ultra-dry compressed air. Lingyu desiccant air dryers feature blower-heated regeneration technology, offering outstanding energy efficiency, simplified maintenance, and reliable performance for critical industrial applications.

Choosing the ideal compressed air dryer is crucial for maximizing efficiency and longevity of your compressed air system. To make the best investment, consider the following key factors:

1. Air Quality Requirements

Start by determining the required pressure dew point for your application.

• High Dew Point (3°C to 10°C): Suitable for general manufacturing processes. A refrigerated air dryer is a cost-effective and widely used solution.

• Low Dew Point (-20°C to -70°C): Required for critical applications such as electronics, pharmaceuticals, and instrumentation. In these cases, a desiccant air dryer is essential to prevent moisture-related failures.

2. Air Flow & Capacity (CFM / m³/min)

Always ensure the compressed air dryer capacity matches your system’s maximum airflow demand. An undersized air dryer may result in poor air quality and system instability. Selecting a dryer designed to handle peak flow conditions ensures consistent performance and long-term reliability.

3. Operating Conditions

Operating conditions have a direct impact on dryer performance. Key factors include ambient temperature, inlet air temperature, system pressure, and installation location. Evaluating these parameters helps determine whether a central compressed air dryer or a point-of-use solution is more suitable.

4. Energy Efficiency and Cost

Beyond the initial purchase price, consider the total cost of ownership. Energy consumption is the primary long-term operating expense. Advanced compressed air dryers with variable frequency control or blower-heated regeneration can significantly reduce energy usage and operating costs over the equipment’s lifespan.

When selecting an air dryer for your compressed air system, efficiency, reliability, and intelligent operation are critical to ensuring smooth and cost-effective performance. Lingyu designs air dryers with cutting-edge technology and strict quality standards, delivering solutions that go beyond basic drying functions. Below, we highlight the key benefits and features that make our air dryers the trusted choice for diverse industrial applications.

1. Superior Energy Efficiency

Advanced technologies such as frequency conversion and blower-heated regeneration enable our air dryers to adapt to real-time operating conditions, reducing energy consumption by up to 30%.

2. Reliable and Stable Operation

Manufactured under strict ISO standards and supported by a rigorous 5S quality control system, Lingyu air dryers ensure stable dew point control and long-term operational reliability.

3. Intelligent Control and Connectivity

Equipped with PLC-based control systems and digital displays, our air dryers support intuitive operation. Selected models feature RS-485 communication for seamless integration into industrial IoT systems.

4. Customized Solutions and Global Support

From system consultation and customized design to commissioning and after-sales service, Lingyu provides end-to-end support to ensure optimal performance of your compressed air system.

There are four main types of compressed air dryers, each designed for specific applications and operating conditions:

Refrigerated Compressed Air Dryer – Ideal for general industrial use and standard moisture removal requirements.

Desiccant Compressed Air Dryer – Designed for applications requiring ultra-low dew points and high air quality.

Membrane Compressed Air Dryer – Compact and efficient, suitable for point-of-use installations.

Deliquescent Compressed Air Dryer – A simple and low-maintenance solution for outdoor or remote environments.

Selecting the right compressed air dryer depends on your air quality requirements, operating conditions, and long-term efficiency goals.

No.3, 2nd Street, yuanle Road, Dongsheng Town, Zhongshan City, Guangdong Province

(WeChat/WhatsApp):+8615756650906

№1:(WeChat/WhatsApp):+8618628146428

№2:(WeChat/WhatsApp):+8613823294942

A compressed air dryer system is an essential part of any industrial compressed air setup. Its main purpose is to remove moisture from compressed air,

When it comes to protecting your compressed air system, drying the air is just as important as compressing it. Two of the most common drying

Introducing Lingyu: a place where cutting-edge DC Series Combined Compressed Air Dryer Systems redefine air quality standards through innovation and precision. Designed to optimize performance

Compressed air containing moisture and water vapors can be a real pain in the neck across various industrial and residential settings. It can cause damage