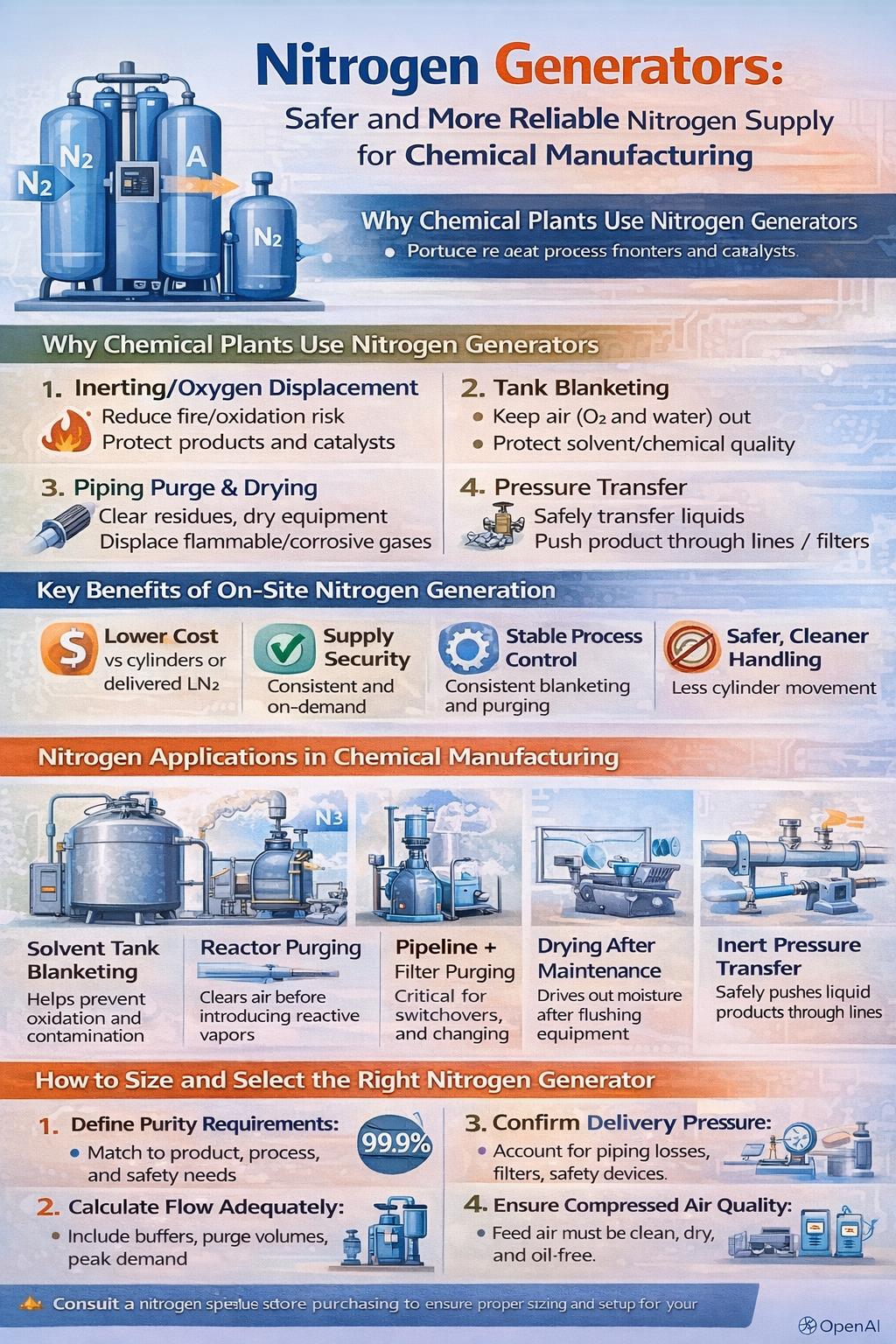

Chemical manufacturing is one of those industries where nitrogen quietly does a lot of heavy lifting. It protects products from oxidation, reduces fire risk in vapor spaces, stabilizes sensitive steps, and makes maintenance safer by purging equipment and lines.

But the way plants source nitrogen is changing. More sites are moving away from cylinder swaps and delivered liquid nitrogen, and toward on-site nitrogen generators for chemical manufacturing—most commonly PSA or membrane systems—because they want predictable supply, fewer logistics headaches, and better long-term cost control.

This article is written in the way people typically search on Google: clear answers, real use cases, and a straightforward selection checklist

Why Nitrogen Is a Core Utility in Chemical Plants

Nitrogen (N₂) is chemically inert in most plant contexts, and when generated correctly it can be clean and dry. That combination makes it ideal for chemical manufacturing tasks where oxygen and moisture create problems.

1) Inerting and oxygen displacement

Many chemical processes involve flammable solvents, reactive vapors, or oxygen-sensitive intermediates. Nitrogen is used to lower oxygen concentration in controlled spaces and reduce oxidation/ignition risk—always within your site’s engineered safety procedures and standards.

2) Tank blanketing

Tank blanketing (sometimes called nitrogen blanketing) uses N₂ to protect the headspace in storage and day tanks. It helps:

keep oxygen out (reducing oxidation and degradation)

reduce moisture pickup (preventing hydrolysis and quality drift)

reduce contamination risk during breathing/filling cycles

This is common for solvents, resins, oils, monomers, and other oxygen- or moisture-sensitive materials.

3) Purging lines, vessels, and reactors

Purging is one of the most common nitrogen consumers in chemical plants—especially in batch operations. N₂ helps remove:

air before introducing process gases

residual vapors after shutdown

moisture after cleaning or maintenance

A reliable nitrogen supply can reduce downtime and improve restart stability.

4) Pressure transfer and “inert pushing”

Nitrogen is often used to move liquids or assist transfers where compressed air is not acceptable (due to oxygen/moisture). It can also support certain filtration steps and controlled pressure operations.

Why Chemical Manufacturers Prefer On-Site Nitrogen Generation

Delivered nitrogen works—but it comes with real-world pain points in chemical operations:

delivery delays (especially remote sites or restricted access)

cylinder handling workload and safety exposure

variable monthly costs and supplier dependency

pressure/flow inconsistency during high-demand events (purging, turnarounds)

What on-site nitrogen generators change

Supply security

Nitrogen becomes an internal utility rather than a delivery item.

Lower total cost over time

You’re primarily paying electricity + maintenance instead of transport + margin + handling.

Better process consistency

More stable pressure and availability for blanketing/purging routines.

Less logistics friction

Fewer cylinders and fewer urgent deliveries.

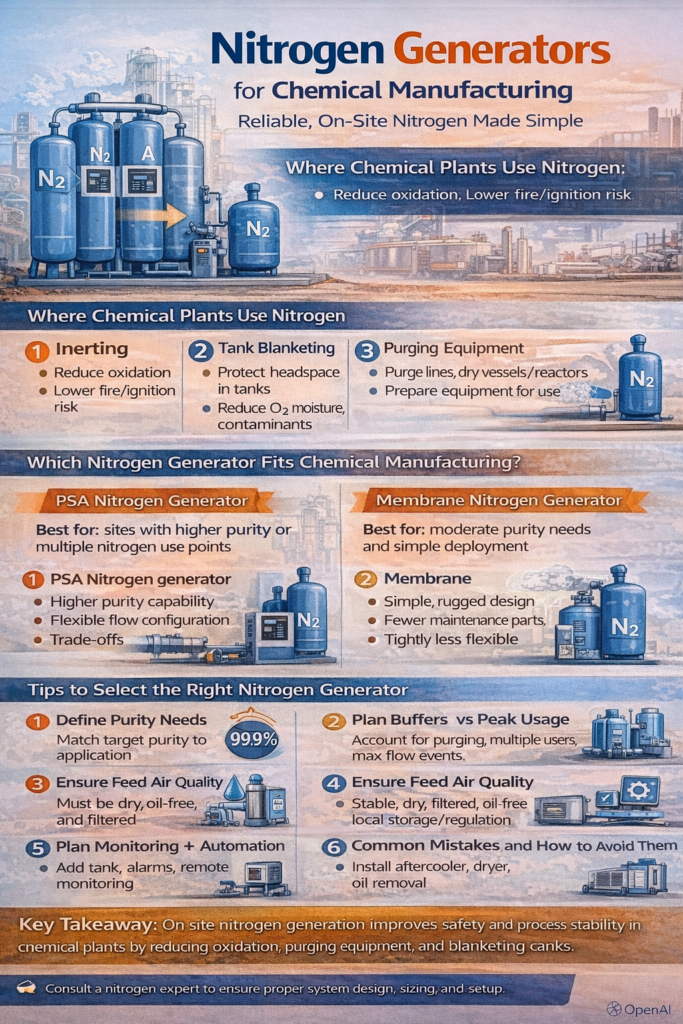

PSA vs Membrane Nitrogen Generators: Which Fits Chemical Manufacturing?

Most on-site nitrogen generators for chemical plants fall into two categories.

PSA nitrogen generators (Pressure Swing Adsorption)

Where PSA usually wins

Sites with multiple use points (blanketing + purging + transfers)

Plants with higher purity needs, or different purity needs across processes

Facilities planning to scale nitrogen use over time

Strengths

flexible configuration across a broad range of flows/purities (by design)

strong fit for “plant utility” nitrogen serving many departments

good life-cycle economics when demand is steady

What to plan for

PSA performance depends heavily on feed air quality

valves and filtration require periodic maintenance

Membrane nitrogen generators

Where membrane usually wins

moderate purity applications

simpler, rugged operation with fewer moving parts

compact footprints and quick response

Strengths

mechanically simple

often very reliable when properly pre-filtered

good choice when purity requirements are clearly moderate and stable

Trade-offs

achieving higher purity can require more air (lower efficiency)

best when your nitrogen specification fits the membrane’s economical zone

Fast rule of thumb

If you need flexibility or higher purity capability: PSA is often the safer default.

If you prioritize simplicity and moderate purity: membrane can be an excellent fit.

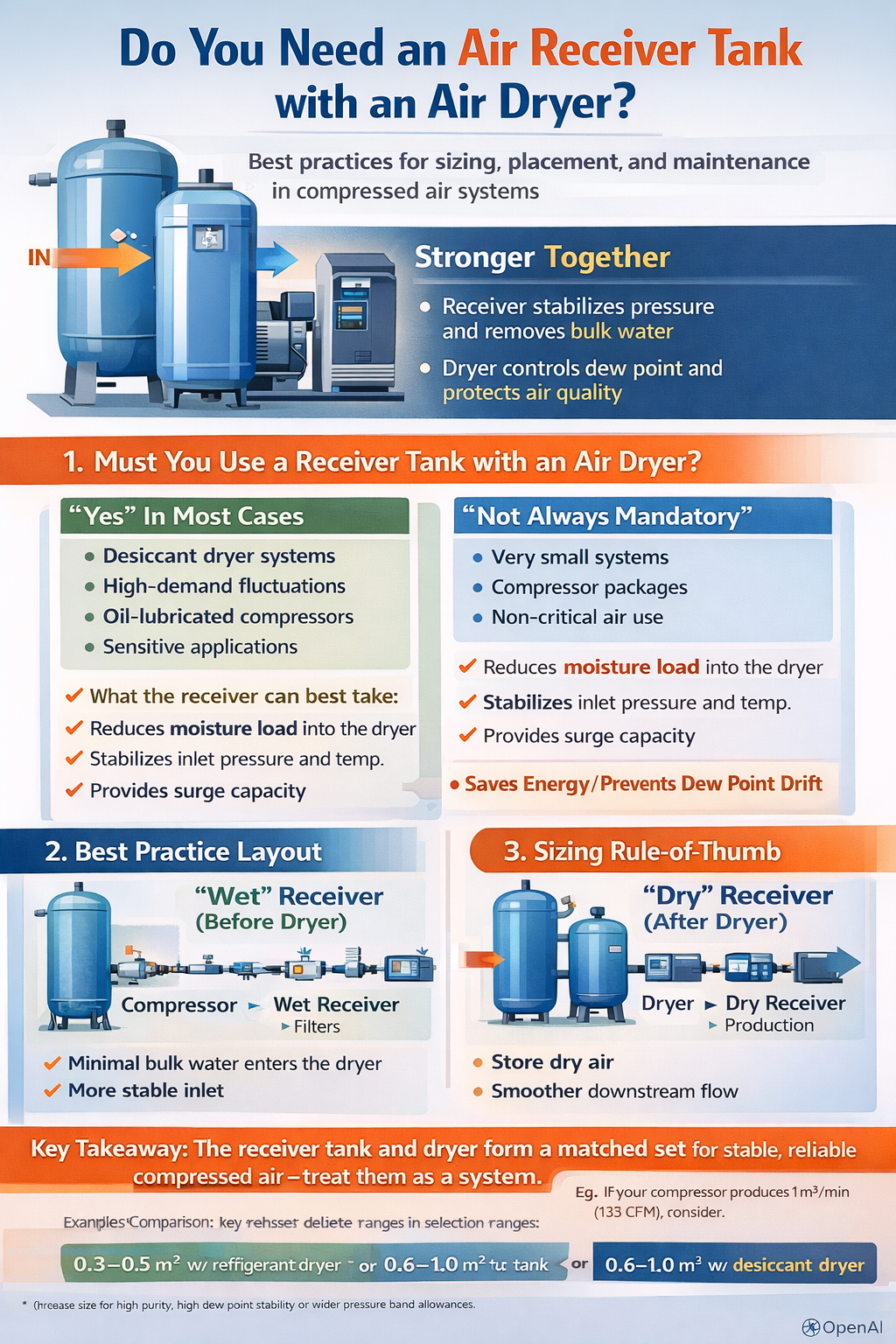

The Real “Make-or-Break” Factor: Feed Air Quality

A nitrogen generator is not a standalone box—it’s a system. In chemical manufacturing, the most common root cause of nitrogen issues (purity drift, valve sticking, unstable output) is poor compressed air quality feeding the generator.

At minimum, plan for:

effective bulk water removal (aftercooler + separator + drains)

solid particulate filtration (dust/pipe scale protection)

oil aerosol control (especially with lubricated compressors)

stable dryness (often a dryer upstream for reliable operation)

If your plant air system struggles with condensate or oil carryover, fix that first or build a dedicated air treatment package for the nitrogen generator.

How to Choose Nitrogen Generators for Chemical Manufacturing (Buyer Checklist)

This is the part most procurement and engineering teams search for: “how do I spec it correctly?”

1) Start by listing nitrogen applications

Create a simple table:

application (blanketing / purging / transfer / inerting)

continuous vs intermittent

expected flow and peak flow

required pressure at point-of-use

purity requirement (if known)

This prevents oversizing and avoids buying “maximum purity” when only one use point needs it.

2) Define purity based on use, not assumptions

Chemical plants often have mixed requirements:

tank blanketing may be less demanding than sensitive reaction protection

purging may demand volume more than extreme purity (depending on method and risk assessment)

certain processes/catalysts may require tighter oxygen control

The right purity is the one that meets:

product quality requirements

process stability targets

safety and compliance requirements (site standards)

3) Size for peaks (and use buffer storage smartly)

Purging creates spikes. Turnarounds create spikes. Simultaneous tasks create spikes.

Instead of oversizing the generator massively, many plants add:

a nitrogen buffer tank to cover peak events

controlled distribution to avoid pressure dips

A buffer tank often improves:

pressure stability

purity stability (less cycling stress)

operator confidence during purge-heavy operations

4) Confirm delivery pressure where it matters

Don’t size pressure at the generator outlet only. Consider:

distance to the farthest point-of-use

pressure drops across filters/regulators

flow-dependent pressure losses during peak events

If some users need higher pressure, you may need:

zoning (different pressure headers)

a booster for a specific line

local storage/regulation

5) Decide PSA vs membrane based on the “worst case”

If one part of the plant needs higher purity or tighter control, don’t accidentally under-spec the whole system. You can solve this in two ways:

choose a system that covers the most demanding use, or

use a base generator + local polishing/boosting strategy for the demanding point

6) Plan monitoring and controls (especially for critical operations)

Common add-ons in chemical manufacturing:

oxygen analyzer (purity verification)

alarms and interlocks where required by safety design

remote monitoring for maintenance planning

auto-economy modes when demand is low

Common Mistakes (and How to Avoid Them)

Mistake 1: Buying based on average consumption only

✅ Fix: include purge volumes, simultaneous users, and future growth; add buffer storage.

Mistake 2: Treating nitrogen generation as separate from air treatment

✅ Fix: design compressor + filtration + drying + generator as one integrated utility.

Mistake 3: Overbuying purity “just in case”

✅ Fix: match purity to actual applications; use targeted solutions for special points.

Mistake 4: Ignoring distribution losses

✅ Fix: calculate pressure drop and header sizing; poor piping can waste capacity.

Mistake 5: No plan for uptime

✅ Fix: define criticality and consider redundancy or backup supply for key processes.

FAQ (Google-style)

Are nitrogen generators safe for chemical manufacturing?

They can be, when engineered correctly and operated under plant safety procedures. Nitrogen can create oxygen-deficient atmospheres, so proper ventilation, monitoring, training, and compliance with site standards are essential.

Do chemical plants typically choose PSA or membrane?

Many choose PSA when they need higher purity capability or flexibility across multiple applications. Membrane is popular for moderate purity needs and simpler operation. The best choice depends on your purity, flow, and operating profile.

Do I need a nitrogen storage tank with a generator?

Often yes—especially for purge-heavy plants. A buffer tank smooths peaks, stabilizes pressure, and can reduce the required generator size.

What’s the biggest cause of nitrogen generator problems in chemical plants?

Feed air quality issues (water, oil carryover, particulates) and undersizing for peak demand are two of the most common causes of unstable performance.

Final Takeaway

Nitrogen generators for chemical manufacturing are less about “making nitrogen” and more about upgrading a plant utility: stable, on-demand, predictable nitrogen for blanketing, purging, transfers, and safety-driven inerting strategies.

If you size the system around real demand, protect it with clean/dry compressed air, and add the right buffer/monitoring, on-site nitrogen can reduce operating cost while improving process stability and operational resilience.

If you want, share these four inputs and I’ll help outline a spec-ready configuration:

target purity (or your applications if unsure)

average + peak flow demand

required delivery pressure at the farthest user

your current compressed air conditions (oil-free vs lubricated, dew point, filtration)