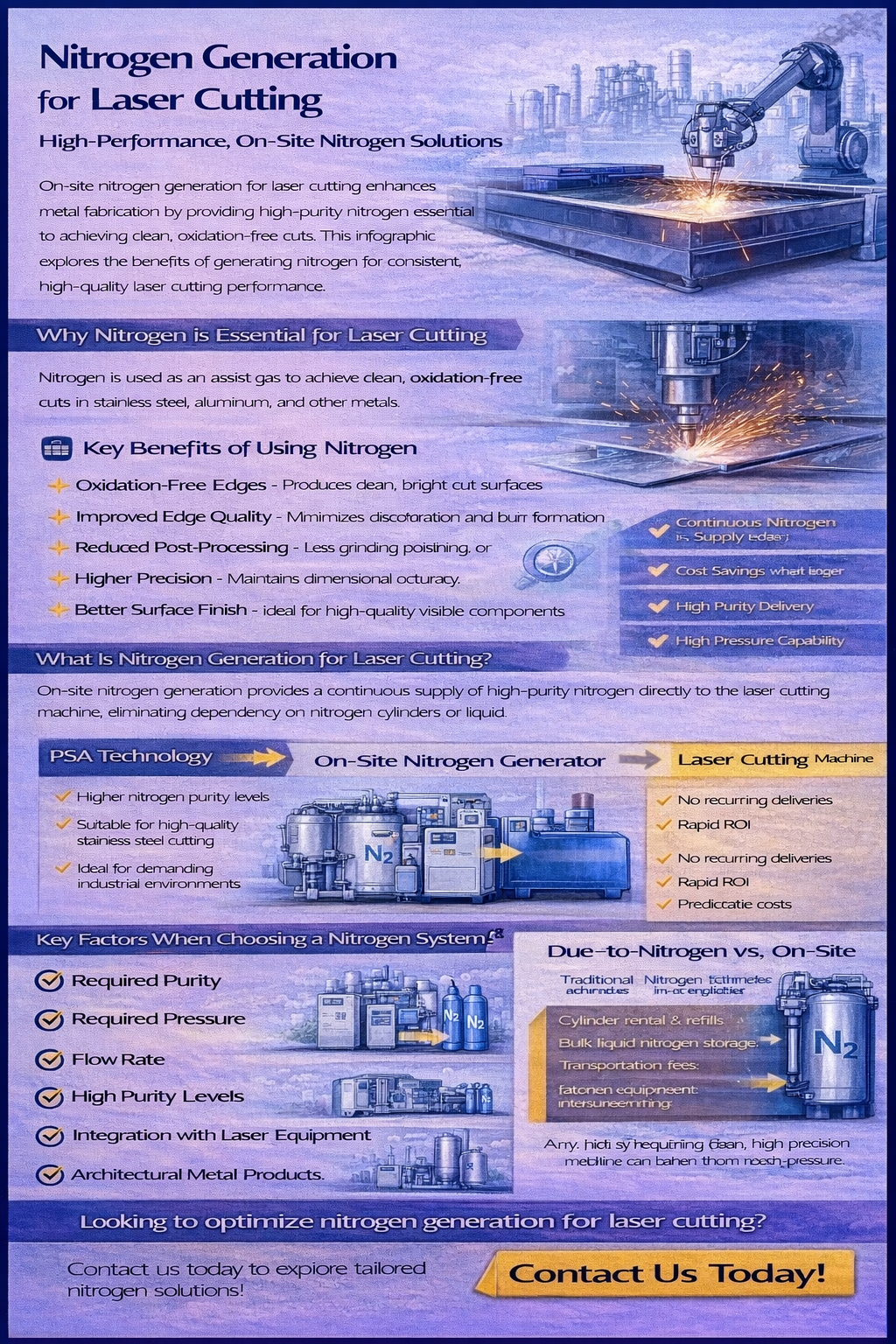

In modern metal fabrication, laser cutting technology plays a critical role in achieving high precision, clean edges, and efficient production. To ensure optimal cutting quality, a stable and high-purity nitrogen supply is essential. A nitrogen generator for laser cutting provides an efficient, cost-effective, and reliable solution for producing nitrogen on-site, eliminating dependence on bottled or liquid nitrogen.

Why Nitrogen Is Essential for Laser Cutting

Nitrogen is widely used as an assist gas in laser cutting, especially for stainless steel, aluminum, and other non-ferrous metals. Unlike oxygen, nitrogen prevents oxidation during the cutting process, resulting in:

Smooth, bright cut edges

No oxidation or discoloration

Reduced post-processing requirements

Improved overall product quality

To achieve these results, nitrogen must be supplied at high purity, stable pressure, and consistent flow—requirements that a nitrogen generator is specifically designed to meet.

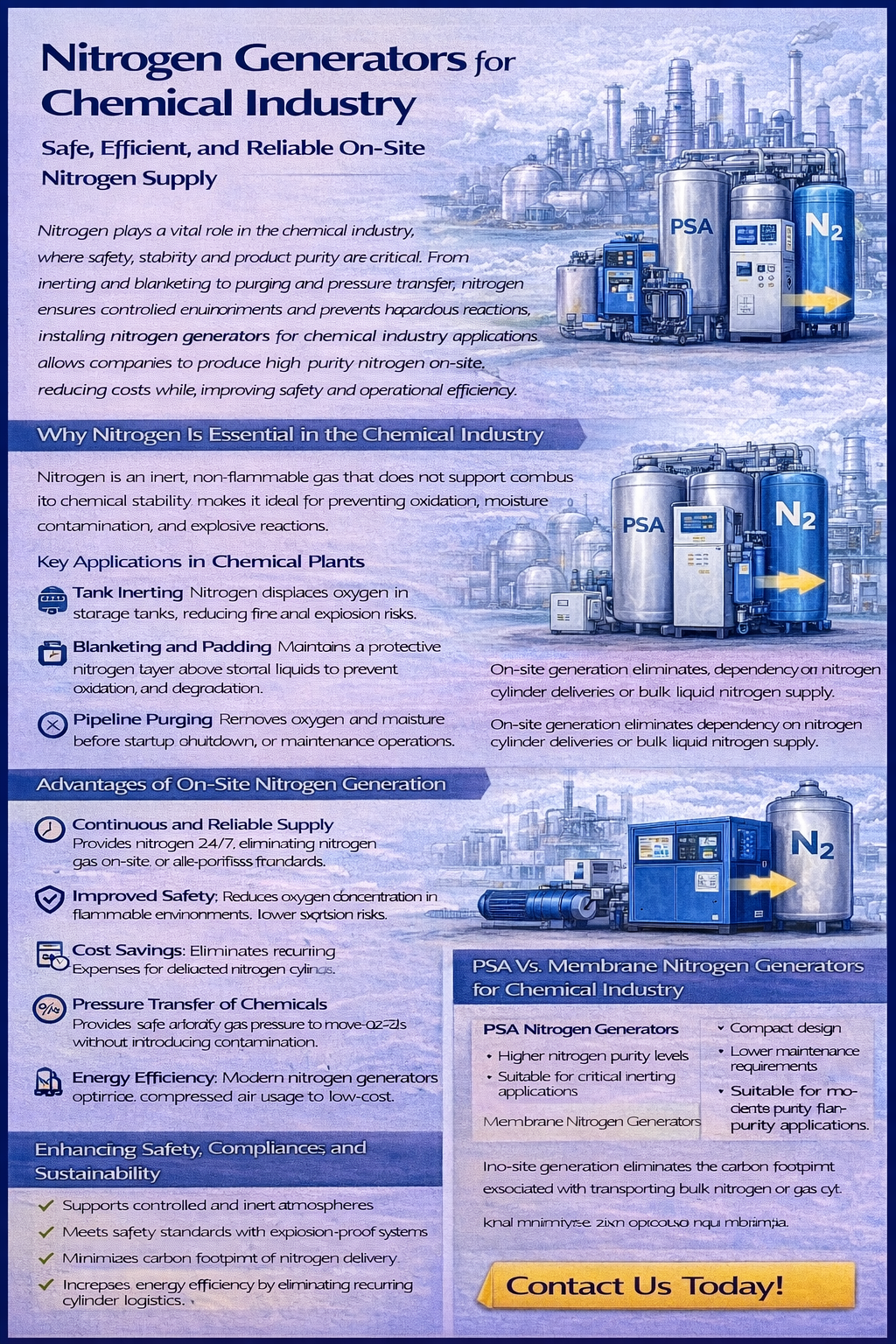

How a Nitrogen Generator for Laser Cutting Works

A nitrogen generator for laser cutting typically uses PSA (Pressure Swing Adsorption) technology. Compressed air passes through carbon molecular sieve (CMS), which selectively adsorbs oxygen and other gases while allowing nitrogen to pass through.

This process delivers nitrogen with purity levels up to 99.999%, suitable for demanding laser cutting applications. The system operates continuously and automatically, ensuring a steady nitrogen supply that matches real-time production needs.

Key Advantages of Using a Nitrogen Generator for Laser Cutting

Significant Cost Reduction

On-site nitrogen generation eliminates recurring costs associated with cylinder replacement, liquid nitrogen delivery, and rental fees.Stable Nitrogen Supply

A nitrogen generator ensures uninterrupted nitrogen availability, avoiding production downtime caused by supply delays.Adjustable Purity and Flow

Nitrogen purity and flow rate can be precisely adjusted according to material type, thickness, and laser cutting parameters.Improved Safety

Removing the need for high-pressure cylinders and cryogenic liquids significantly reduces safety risks in the workshop.Energy-Efficient Operation

Modern nitrogen generators are designed to optimize compressed air consumption, lowering overall energy costs.

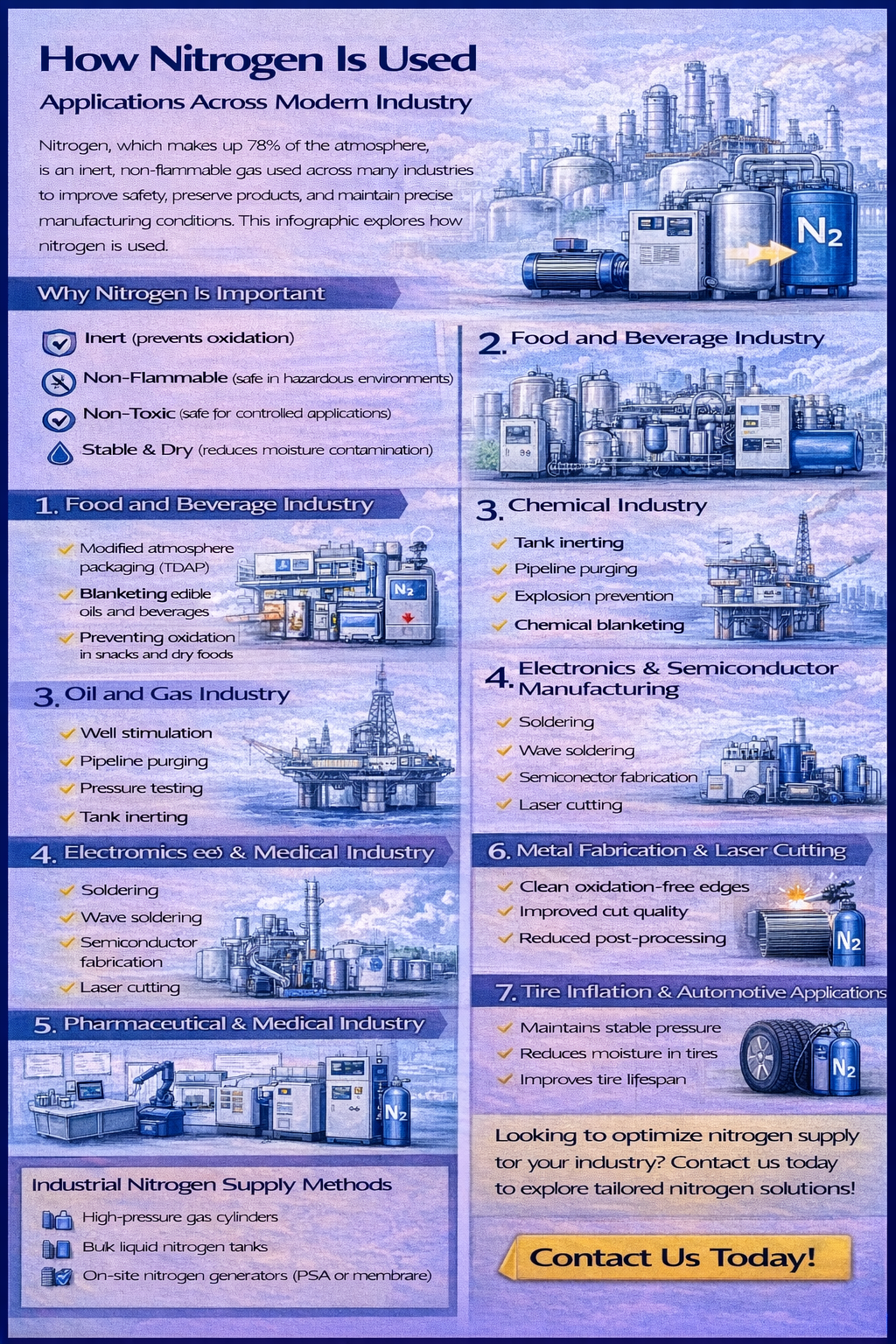

Applications in Laser Cutting Industry

Nitrogen generators are widely used in:

Stainless steel laser cutting

Aluminum and copper cutting

Sheet metal fabrication

Automotive and aerospace component manufacturing

Precision metal processing workshops

Choosing the Right Nitrogen Generator for Laser Cutting

When selecting a nitrogen generator, it is important to consider:

Required nitrogen purity and flow rate

Laser cutting machine specifications

Operating pressure requirements

Energy efficiency and operating costs

Manufacturer experience and after-sales support

A well-designed nitrogen generator system can be seamlessly integrated with existing laser cutting equipment to maximize productivity and reliability.

Conclusion

A nitrogen generator for laser cutting is a smart investment for metal fabrication companies seeking higher cutting quality, lower operating costs, and greater production independence. By producing nitrogen on-site, manufacturers gain full control over their gas supply while improving safety and efficiency. Choosing a high-quality nitrogen generator ensures consistent performance and long-term value for laser cutting operations.