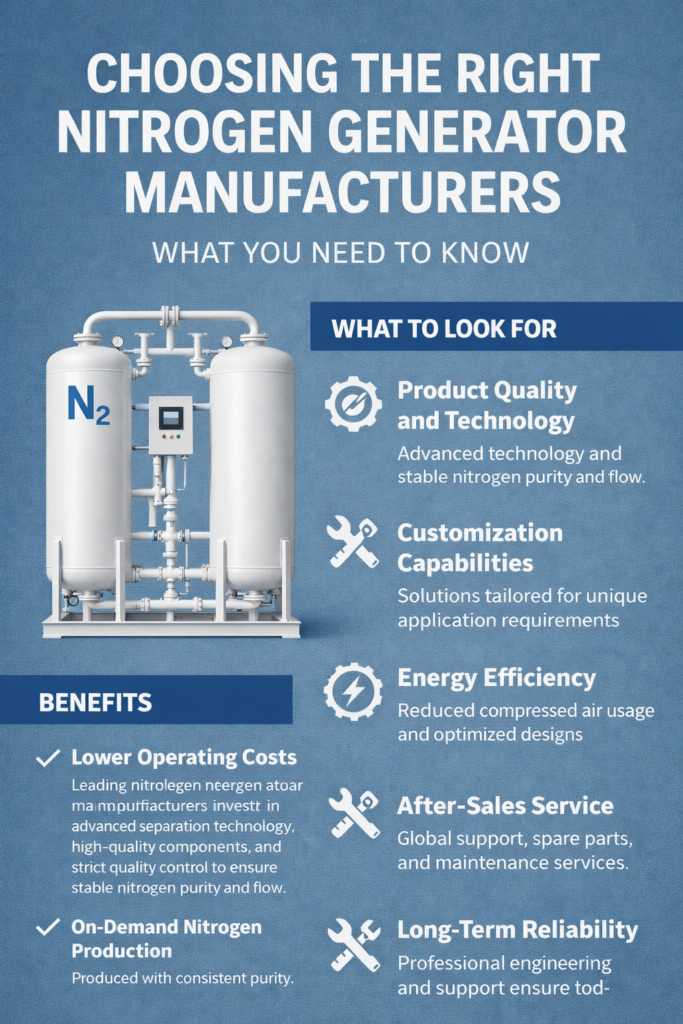

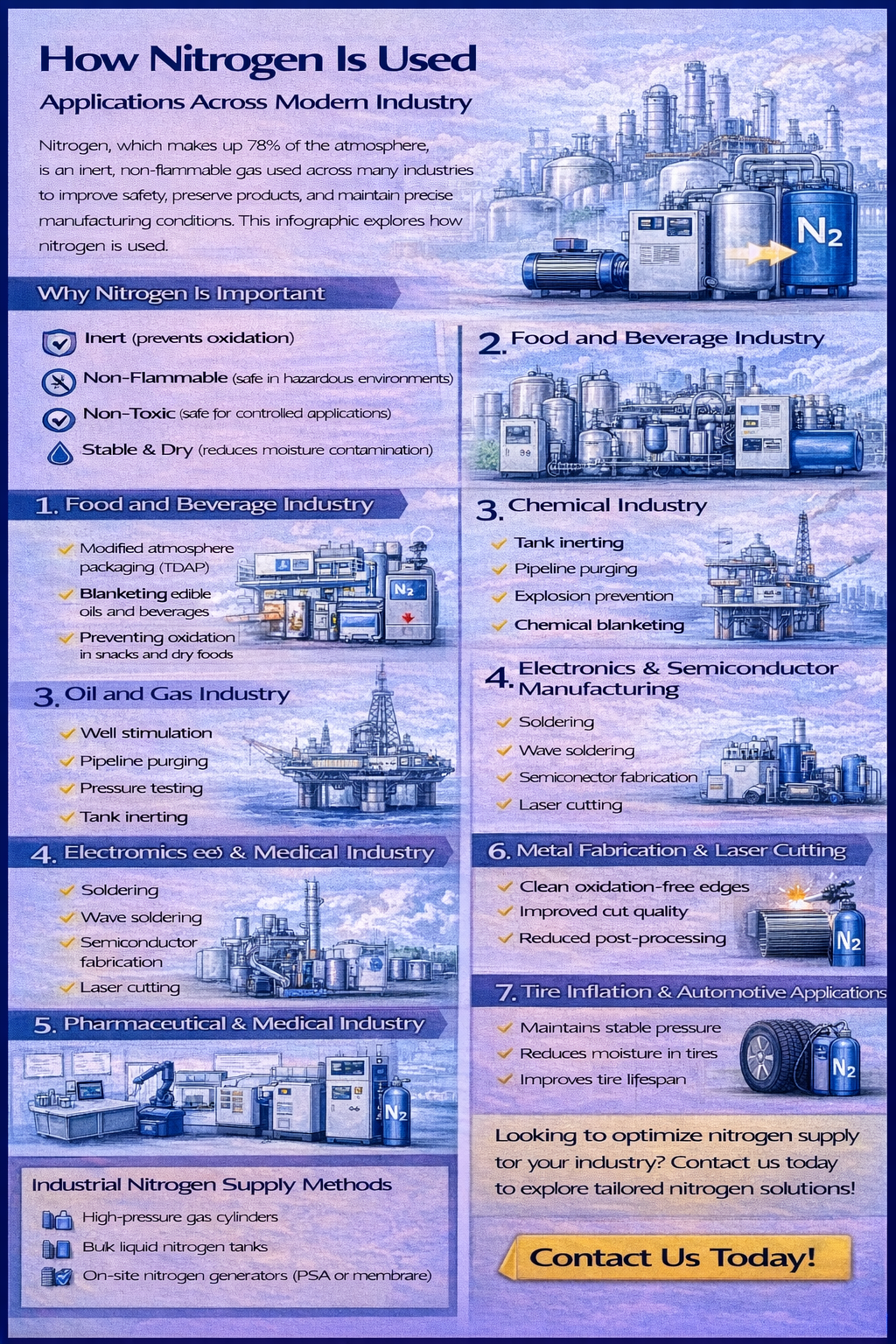

Nitrogen is widely used across industries such as food packaging, pharmaceuticals, electronics, chemicals, and metal fabrication. As demand for on-site nitrogen production continues to grow, more companies are turning to nitrogen generators as a cost-effective and reliable solution. Selecting the right nitrogen generator manufacturers is a critical decision that directly impacts system performance, operating costs, and long-term reliability.

What Do Nitrogen Generator Manufacturers Do?

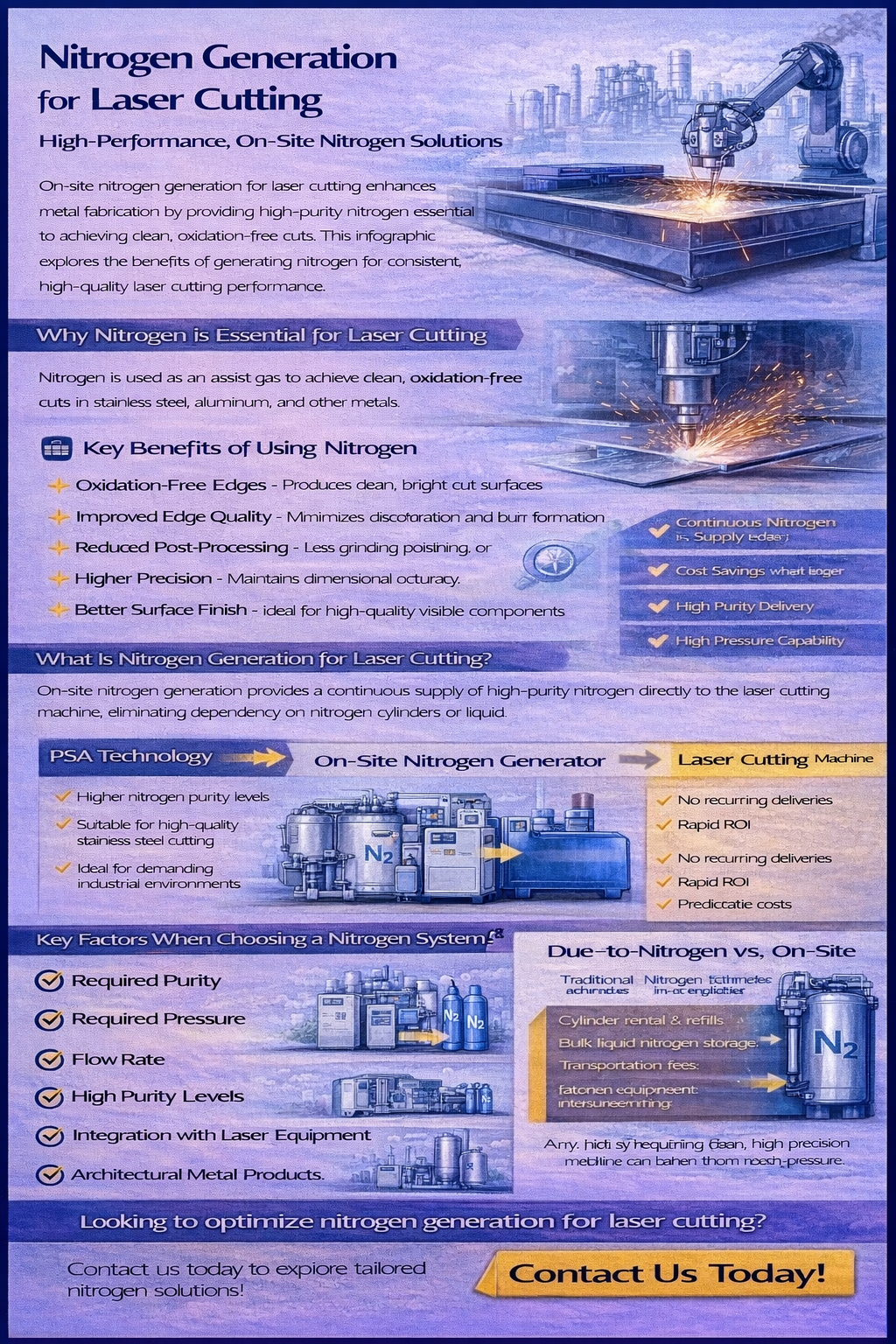

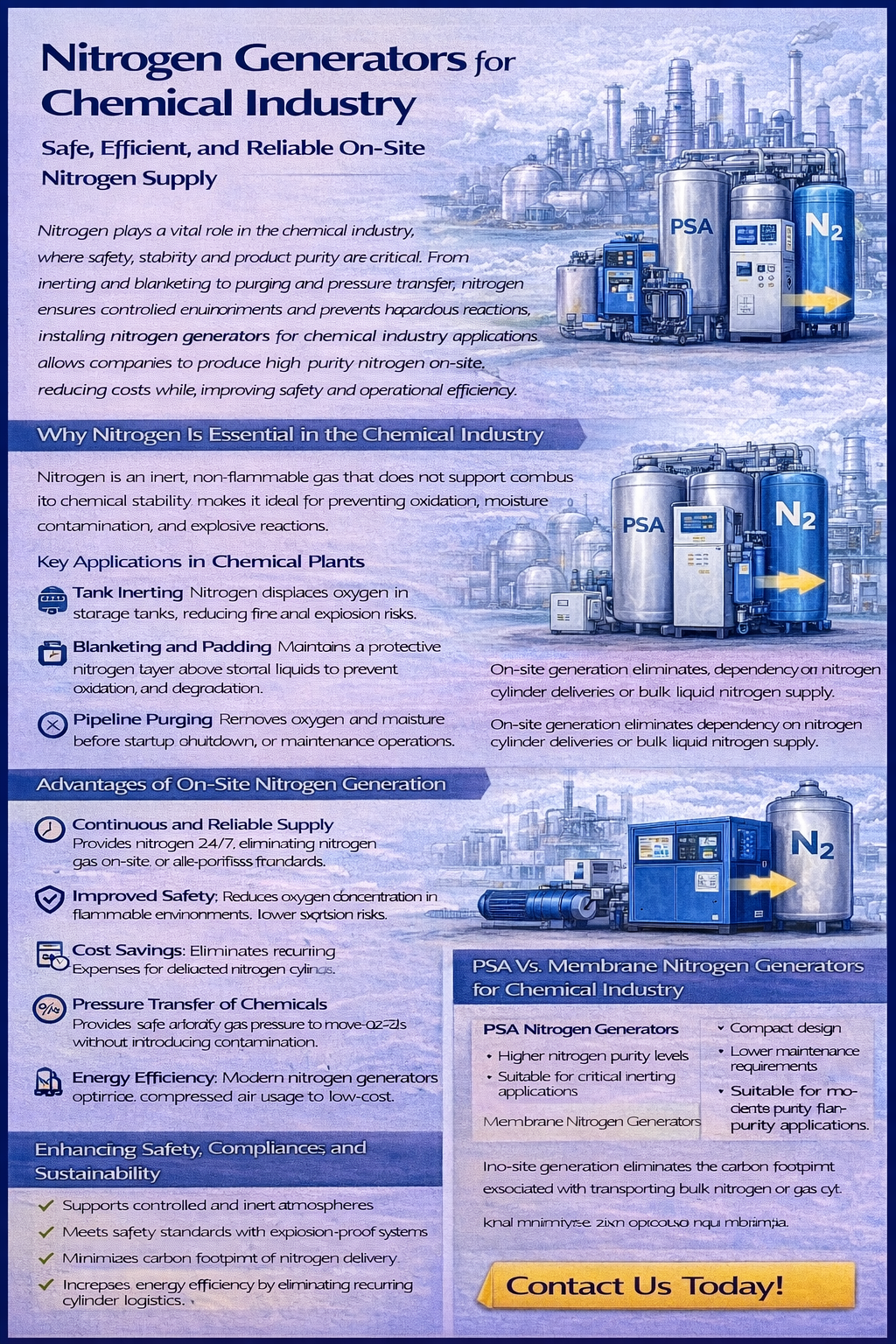

Nitrogen generator manufacturers design and produce systems that separate nitrogen from compressed air. The two most common technologies used are PSA (Pressure Swing Adsorption) and membrane separation.

PSA Nitrogen Generators use carbon molecular sieve (CMS) to adsorb oxygen, delivering high-purity nitrogen suitable for demanding industrial applications.

Membrane Nitrogen Generators use hollow fiber membranes to separate gases, offering compact designs and lower maintenance for applications requiring moderate nitrogen purity.

Reliable manufacturers not only supply the equipment but also provide system engineering, customization, testing, and technical support.

Key Factors to Consider When Evaluating Nitrogen Generator Manufacturers

Product Quality and Technology

Leading nitrogen generator manufacturers invest in advanced separation technology, high-quality components, and strict quality control to ensure stable nitrogen purity and flow.Customization Capabilities

Every application has unique requirements. Reputable manufacturers can customize nitrogen purity levels, flow rates, pressure, and system configurations to match specific industry needs.Energy Efficiency

Energy consumption is a major operating cost. Experienced manufacturers focus on optimized designs that reduce compressed air usage and improve overall system efficiency.Certifications and Compliance

Look for manufacturers that meet international standards such as ISO, CE, or ASME, especially for industries with strict regulatory requirements.After-Sales Service and Support

Strong technical support, spare parts availability, and maintenance services are essential for long-term system reliability. Trusted nitrogen generator manufacturers offer comprehensive after-sales support worldwide.

Benefits of Working with Established Nitrogen Generator Manufacturers

Lower Operating Costs compared to bulk liquid nitrogen supply

On-Demand Nitrogen Production with consistent purity

Reduced Logistics and Safety Risks

Long-Term Reliability backed by professional engineering and support

Conclusion

Choosing the right nitrogen generator manufacturers is key to ensuring efficient, reliable, and cost-effective nitrogen production. By focusing on technology, customization, energy efficiency, and service support, businesses can find a manufacturing partner that delivers long-term value. Investing in a high-quality nitrogen generator not only improves operational efficiency but also provides greater control over nitrogen supply for critical industrial processes.