In any professional painting application—whether automotive refinishing, industrial coating, or precision surface finishing—moisture in compressed air can ruin results. That’s where an air compressor dryer for painting becomes an essential part of your compressed air system, ensuring clean, dry air for flawless coatings every time.

This guide explains why using a dryer matters for painting, how different dryer types work, and how to choose the right solution for your specific application.

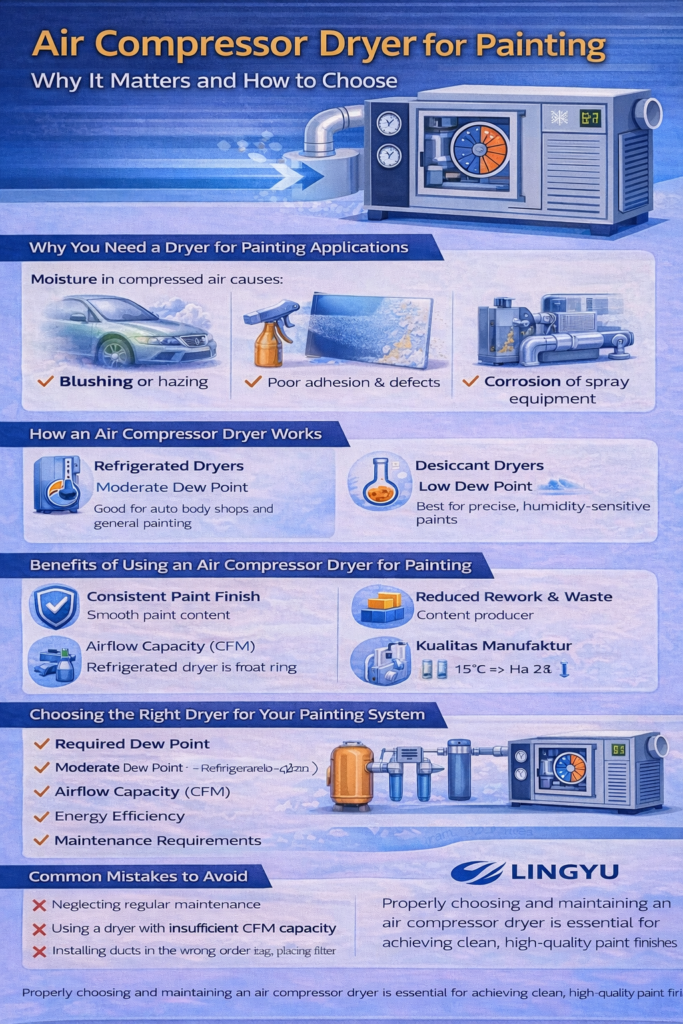

Why You Need a Dryer for Painting Applications

Painting operations depend on compressed air to atomize paint and deliver it smoothly onto surfaces. When moisture remains in the air, it can lead to:

Blushing or hazing on painted surfaces

Runs and sags caused by water droplets mixing with paint

Poor adhesion or finish defects

Equipment corrosion and clogged spray guns

These issues not only compromise quality but also lead to rework, wasted materials, and higher production costs.

An air compressor dryer for painting removes water vapor and minimizes liquid droplets, delivering stable, dry air that supports professional-quality finishes.

How an Air Compressor Dryer Works

An air compressor generates compressed air as it forces ambient air into a smaller volume. This process increases temperature and pushes moisture out of solution. As the air cools in the system, moisture condenses. Without a dryer, that moisture travels through hoses and can reach the paint gun.

Air compressor dryers prevent this by lowering the moisture content of the air before it reaches the tool. The main dryer technologies used in painting applications are:

Refrigerated Dryers

Refrigerated dryers cool the air to a moderate dew point so that water condenses and is removed. These are ideal for general painting shops, auto body shops, and medium-duty production.

Best for: Auto painting, industrial finishing, general painting booths

Desiccant Dryers

Desiccant dryers use moisture-absorbing material (desiccant) to achieve a very low dew point, often necessary for precision coatings, humidity-sensitive paints, or high-end finishes.

Best for: Precision painting, humidity-critical coatings, controlled environments

Key Benefits of Using an Air Compressor Dryer for Painting

Consistent Paint Finish

Dry air prevents moisture from mixing with paint, producing smooth and uniform surfaces.

Reduced Rework and Waste

By eliminating water-related defects, you reduce costly rework and material waste.

Less Equipment Wear

Moisture can lead to rust and corrosion in spray guns, regulators, valves, and hoses.

Improved Production Efficiency

Dry air stabilizes atomization and spray patterns, enhancing throughput and quality.

Choosing the Right Dryer for Your Painting System

When selecting an air compressor dryer for painting, consider the following factors:

Required Dew Point

Moderate dew point (refrigerated dryer) usually suffices for automotive and general industrial painting.

Low dew point (desiccant dryer) is needed when environmental humidity is high or surface quality must be flawless.

Airflow Capacity (CFM)

Match the dryer’s capacity to your compressor’s output. Undersized dryers can’t effectively remove moisture, while oversized units add unnecessary cost.

Operating Conditions

Consider ambient temperature, humidity, and how hard your system runs—e.g., continuous vs. intermittent usage.

Energy Efficiency

Look for dryers with low pressure drop and efficient moisture removal to minimize operating costs.

Maintenance Requirements

Ease of filter changes, drain controls, and indicator systems help reduce downtime.

Installation Tips for Painting Applications

For best performance:

Install the dryer after the compressor and air receiver tank

Use appropriate filtering before and after the dryer to trap oil and particulates

Make sure condensate drains are set correctly

Place the system in a well-ventilated, temperature-controlled area

Proper placement ensures the dryer works efficiently and prolongs service life.

Common Mistakes to Avoid

Even with a quality air compressor dryer, mistakes can reduce its effectiveness:

Ignoring regular maintenance

Using a dryer with insufficient CFM capacity

Installing ducts in the wrong sequence (e.g., placing filters after the paint gun)

Using a dryer that cannot achieve the required dew point

Avoiding these improves reliability and finish quality.

Conclusion

An air compressor dryer for painting is more than an accessory—it’s a critical component in any compressed air painting system. By removing moisture before the air reaches spray equipment, a proper dryer protects your finish, reduces waste, and enhances overall productivity.

Whether you choose a reliable refrigerated dryer for general painting or a desiccant dryer for precision coatings, matching the dryer to your workflow and environment is key to professional, high-quality results.